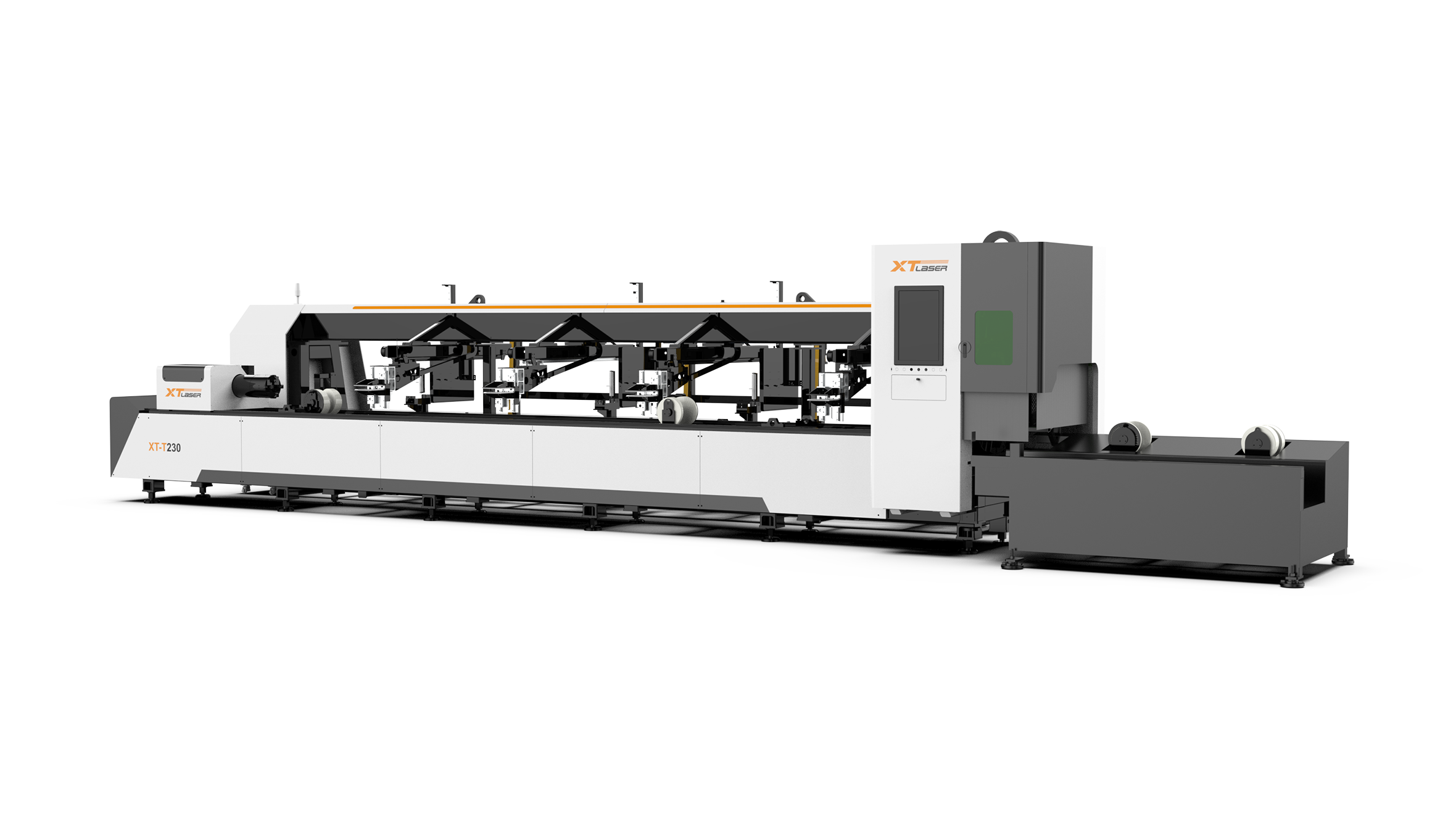

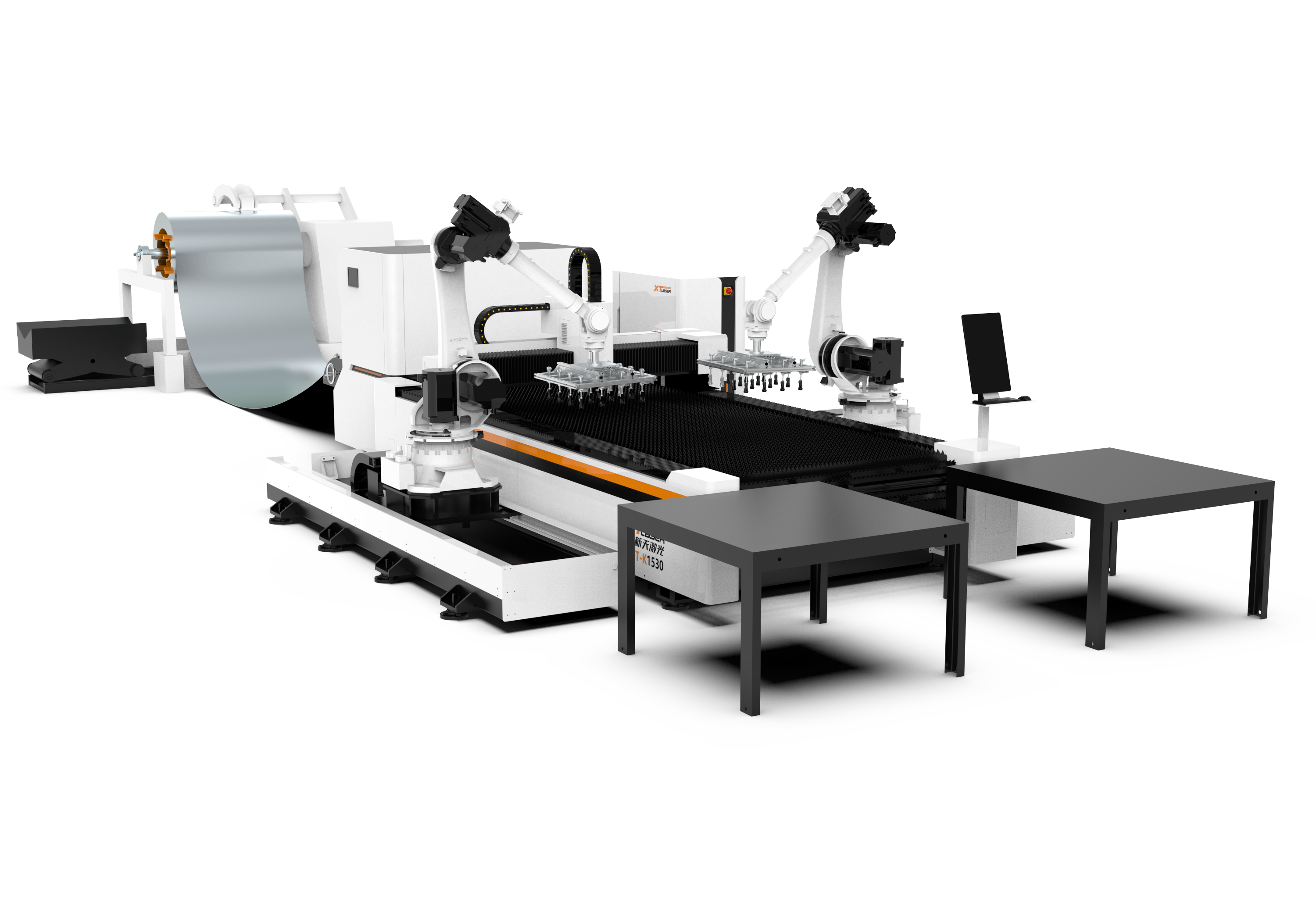

Star Products

VIEW MORE

SKIP

Star Products

Laser cutting machines

Marking machines

Welding machines

Cleaning machines

Automation

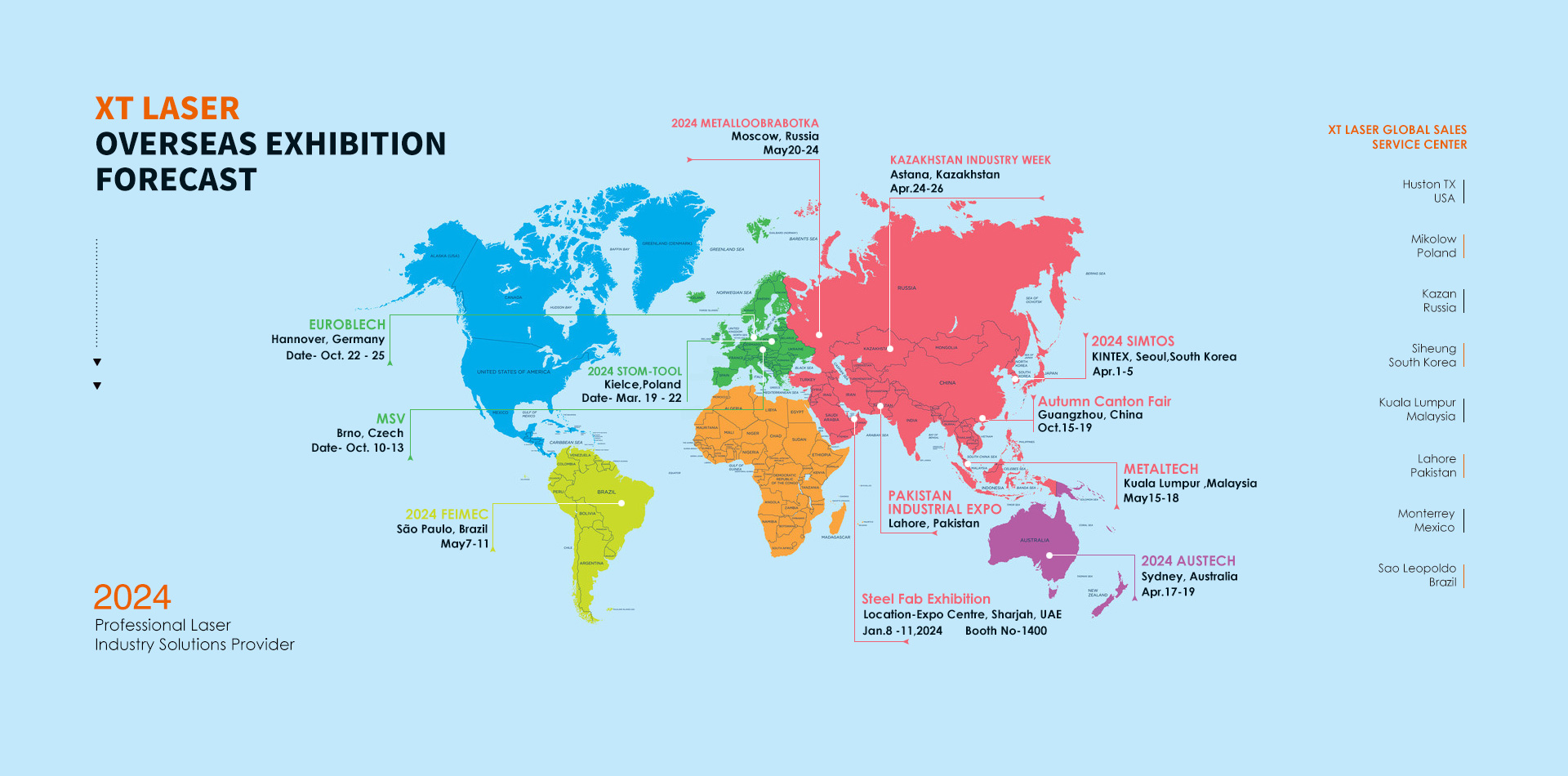

Global layout

PROVINCESCITIES AND MORE THAN 160 COUNTRIES AND REGIONS

ACROSS THE COUNTRY

Xintian Laser station in Paris Office

PHONE

400-8881234

E-MAIL

wanghao@xintian.com

address

52,rue de Rivoli 75001 Paris

Partners

Together with the XT laser to create a better tomorrow

Together with the XT laser to create

CONTACT US

Together with the XT laser to create

News Center

How a 6000 Watt Laser Cutting Machine Boosts Productivity and Precision

2023.05.09

-

The Fiber Laser Cutting Machine 3000W A Superhero for Manufacturing

2022.09.22 -

Laser cutting machines for metal types, features, selection rules

2022.09.22 -

Guide to choosing a metal cutting laser machine

2022.09.22 -

Fiber Laser 1KW Cutting Machine The Key to Boosting Your Manufacturing Efficiency

2022.09.22 -

2KW Fiber Laser Cutting Machine The Benefits and Advancements

2022.09.22 -

Jinan Xintian Technology Co., Ltd.

2022.09.22 -

Laser cutting machine principle–Jenny

2022.09.22 -

Metal fiber laser cutting machine purchase guide:Claudia

2022.09.22

News Center

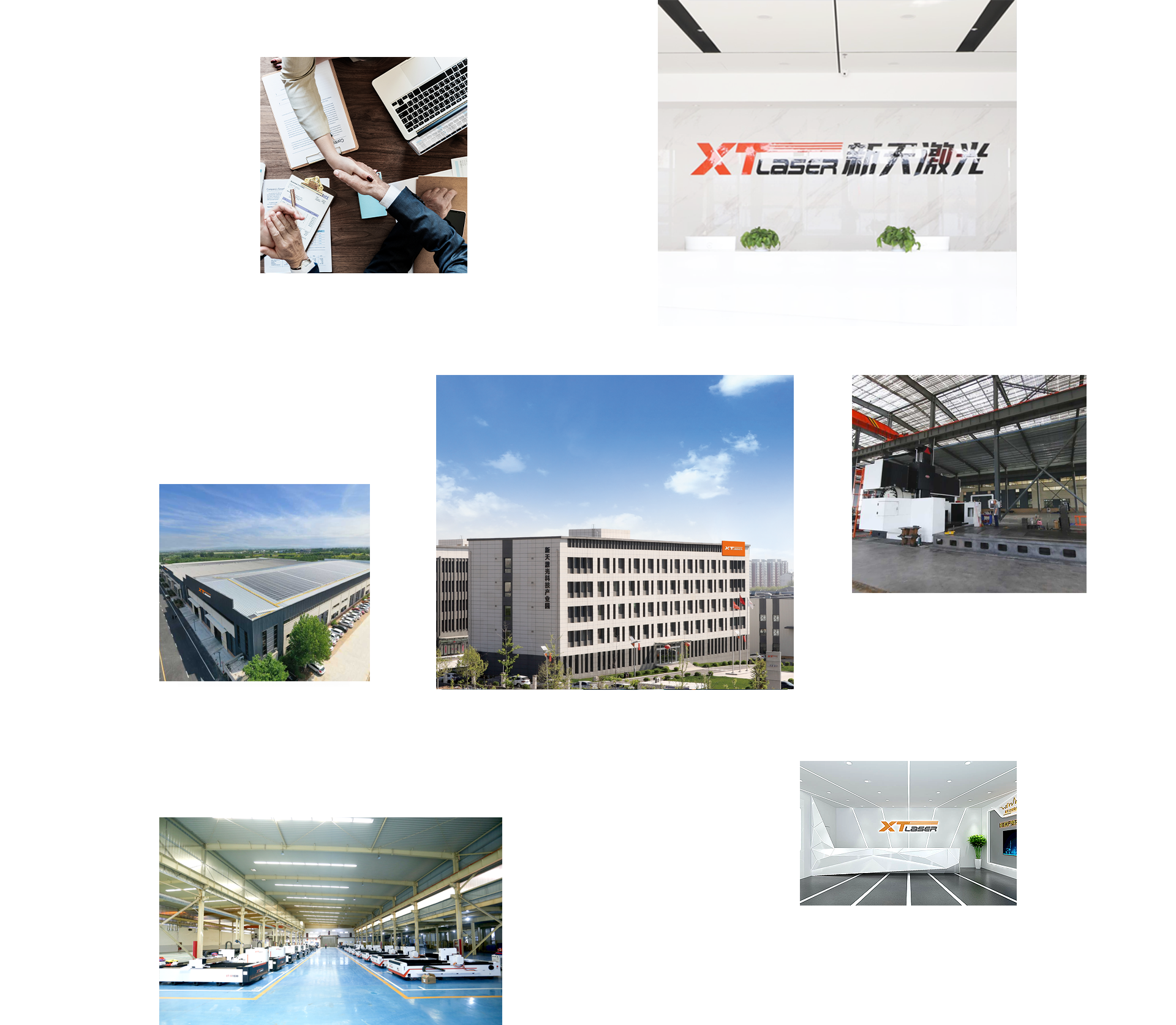

About Us

Helps employees continue to grow and share wealth, and strive

for a happy life in the family and society.

VIEW MORE

for a happy life in the family and society.

About Us

Helps employees continue to grow and share wealth, and strive

for a happy life in the family and society.

2004

XTLASER was established in 2004

200

Professional skill worker

160

Export to 160 countries or regions

50000

Cumulative number of customers served