Guide to choosing a metal cutting laser machine

Laser metal cutting machines (metal cutters) are rightly ranked among the leading innovative equipment used in various sectors of the economy: metallurgy, mechanical engineering, furniture production and others. This is because with their help it is possible to produce details of the most complex configuration with a high degree of accuracy without the need for further processing of the contour. Thanks to minimum cutting thicknesses and rational cutting of the sheets, it is possible to achieve waste-free production.

Further advantages of this process are

High production output;

availability of an automated control system;

lower production costs.

Selection criteria for laser cutting machines

Many managers sooner or later think about providing their businesses and companies with this kind of high-tech machinery. After all, to have at least one laser machine for cutting metal in production - it means to give up old and inefficient equipment and with minimum energy costs to provide the necessary volume of parts and blanks assembly area. But because there are several types of such equipment, and even at a high cost, the choice of model for each case should be approached individually. Let's find out what to look for when selecting a laser cutting machine for a specific application.

Features of a laser cutter

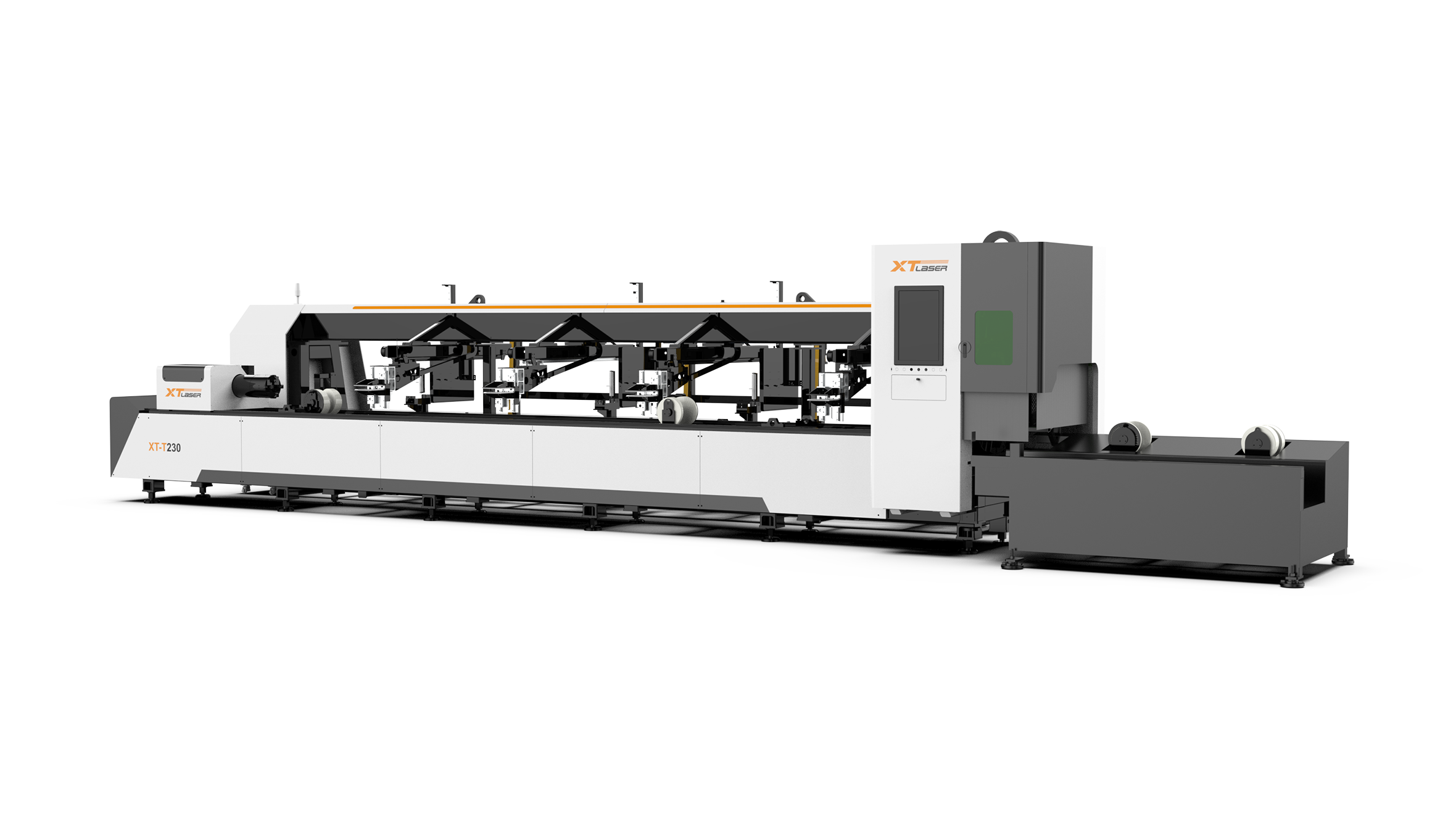

To begin with, let's understand the design of a laser cutter and the peculiarities of its operation. A laser cutter, the same as a metal cutter, consists of the following nodes:

An emitter, which generates a narrowly focused pulse or stream of photons;

A gas transfer system that cools the transmitter and blows the molten metal out of the working area;

a drive used to move the transmitter over the cutting surface;

coordinate table on which a metal sheet or a workpiece to be machined is placed;

automated control system (ACS) or CNC.

Laser cutting technology is based on vaporization or blow-out of thin layers of molten metal by means of a flow of gaseous mixture under the influence of powerful generators (lasers). This process guarantees a high cut quality on all types of steel, but also on all types of steel sheet.

this method of processing guarantees a high cut quality for all types of steels as well as non-ferrous metals and alloys.

Types of lasers: comparison of gas and fibre lasers

Let us define the laser types, because the principle of laser systems is to focus the beam, which provides a high concentration of energy on the surface of a material. This beam has a diameter of only a few tens of millimetres, which allows small cutting thicknesses. The process of melting and changing the structure of the metal occurs when the beam reaches a certain power level.

The following types of lasers are available:

gas lasers in which a mixture of carbon dioxide, nitrogen and helium plays the role of the active medium;

Fibre lasers which use optical fibres as an active medium;

Solid state lasers where crystals and special types of glass take the place of the active medium.

diode.

Let's take a look at the top two in the list and compare them with each other. In doing so, we will draw attention to three important points to be considered when selecting a laser machine:

The efficiency of cutting any material depends on the wavelength of radiation. Fiber lasers with short wavelengths, for example, show high performance in cutting thin sheet metal up to 3 mm thick. Gas lasers with a longer emission wavelength show excellent results in cutting thicker metal sheets.

Fiber lasers are more expensive in comparison to their gas counterparts.

Equipment equipped with fiber lasers is small in size and has a long service life of 100,000 hours due to the quality of the fiber optic and absence of overheating.

The spot emitted by a fibre laser beam is small in size and has a good depth of field in comparison to a gas laser.

More precise grades can be achieved in metal machining with fibre lasers

Working field: What to consider

When selecting a laser cutting machine you also have to determine the dimensions of the working area of the X-Y table. If you need to cut out material, a model with a larger table is the right choice. If, however, you are looking for ideas related to arts and crafts, a smaller metal laser cutter may be the way to go.

When purchasing laser metal cutting equipment, you should be aware of the following: while the laser power can be increased, the table cannot be changed - it changes with the machine.