The Fiber Laser Cutting Machine 3000W A Superhero for Manufacturing

Introduction:

Fiber laser cutting machines have become a popular tool in the manufacturing industry due to their high precision and speed. The 3000W model is especially popular because of its high power output, making it a top choice for cutting thicker materials. In this article, we'll delve deeper into the benefits of fiber laser cutting machines, with a focus on the 3000W model.

What is a Fiber Laser Cutting Machine 3000W?

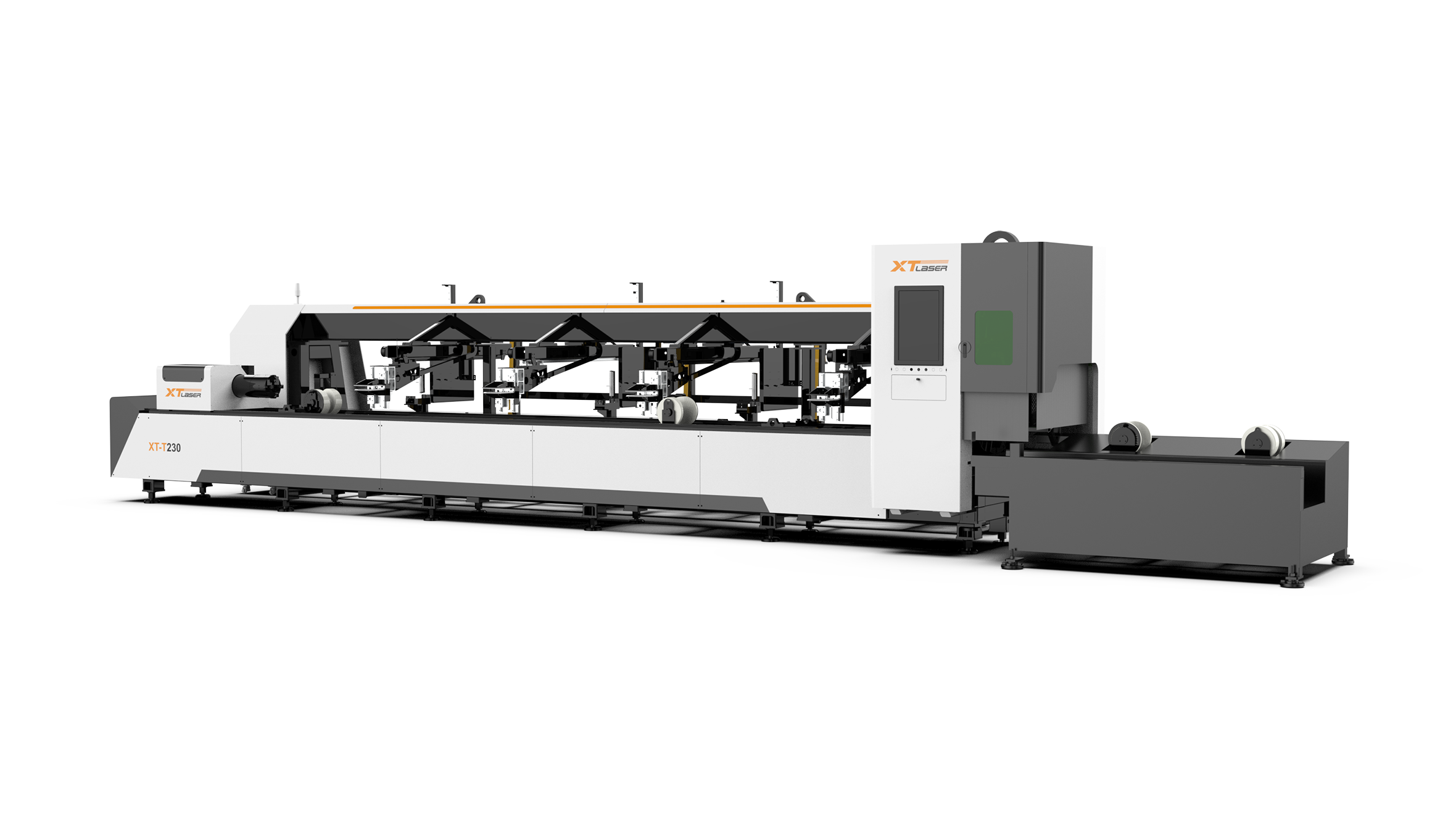

A fiber laser cutting machine 3000W is a type of industrial cutting tool that uses a high-powered fiber laser to cut through various materials. These machines are known for their high precision, speed, and versatility. They can cut through metals like steel, aluminum, and copper, as well as non-metallic materials like plastics, wood, and ceramics. The 3000W model stands out for its ability to cut through thicker materials.

Benefits of a Fiber Laser Cutting Machine 3000W:

High Speed and Precision: The 3000W model offers high speed and precision, allowing for faster and more accurate cutting of materials. This can result in increased productivity and cost savings for businesses. With its high power output, the 3000W model can handle thicker materials than other fiber laser cutting machines.

Versatility: The 3000W model can cut through a wide range of materials, making it a versatile tool for various industries. In addition to metals and non-metallic materials, it can cut through textiles, leather, and composites.

Low Maintenance: Fiber laser cutting machines require minimal maintenance, which can save businesses time and money in the long run. The 3000W model is no exception, with its sturdy design and reliable performance.

Energy Efficiency: Fiber laser cutting machines are more energy-efficient compared to traditional cutting tools, resulting in lower energy costs for businesses. The 3000W model uses less power than other machines of its caliber, further increasing its energy efficiency.

Applications of Fiber Laser Cutting Machine 3000W:

Automotive Industry: The 3000W model is commonly used in the automotive industry for cutting various parts such as body panels, frames, and exhaust systems. Its high power output makes it ideal for cutting through thick metal sheets.

Aerospace Industry: The high precision and speed of the 3000W model make it ideal for cutting parts for the aerospace industry such as airplane wings and fuselage. Its ability to cut through composites and other materials used in the aerospace industry is a key advantage.

Medical Industry: The 3000W model can be used for cutting medical devices such as surgical instruments, implants, and prosthetics. Its precision and versatility make it a top choice for medical applications.

Construction Industry: The 3000W model can be used for cutting construction materials such as steel beams, pipes, and plates. Its high power output and versatility make it a valuable tool for construction companies.

Fiber laser cutting machines are the superheroes of the manufacturing industry! And if we were to pick one particular model, the Fiber Laser Cutting Machine 3000W would definitely be the Thor of the bunch. With its high power output and versatility, it can cut through a wide range of materials like steel, aluminum, copper, plastics, wood, and even ceramics.

One of the key advantages of the 3000W model is its high speed and precision, making it a favorite among manufacturers. It can cut through thicker materials like a hot knife through butter, which is why it's often the go-to tool in the automotive, aerospace, medical, and construction industries. It's so versatile that it can even cut through composites and other materials used in the aerospace industry.

Another cool thing about this fiber laser cutting machine is that it requires minimal maintenance. Yes, you heard that right - it's low-maintenance and can save businesses time and money in the long run. Plus, it's energy-efficient and uses less power than other machines of its caliber. So, not only can you save money on maintenance, but you can also save on your energy bills.So if you're looking for a cutting-edge solution for your manufacturing needs, the 3000W model might just be the superhero you need.