How a 6000 Watt Laser Cutting Machine Boosts Productivity and Precision

Introduction

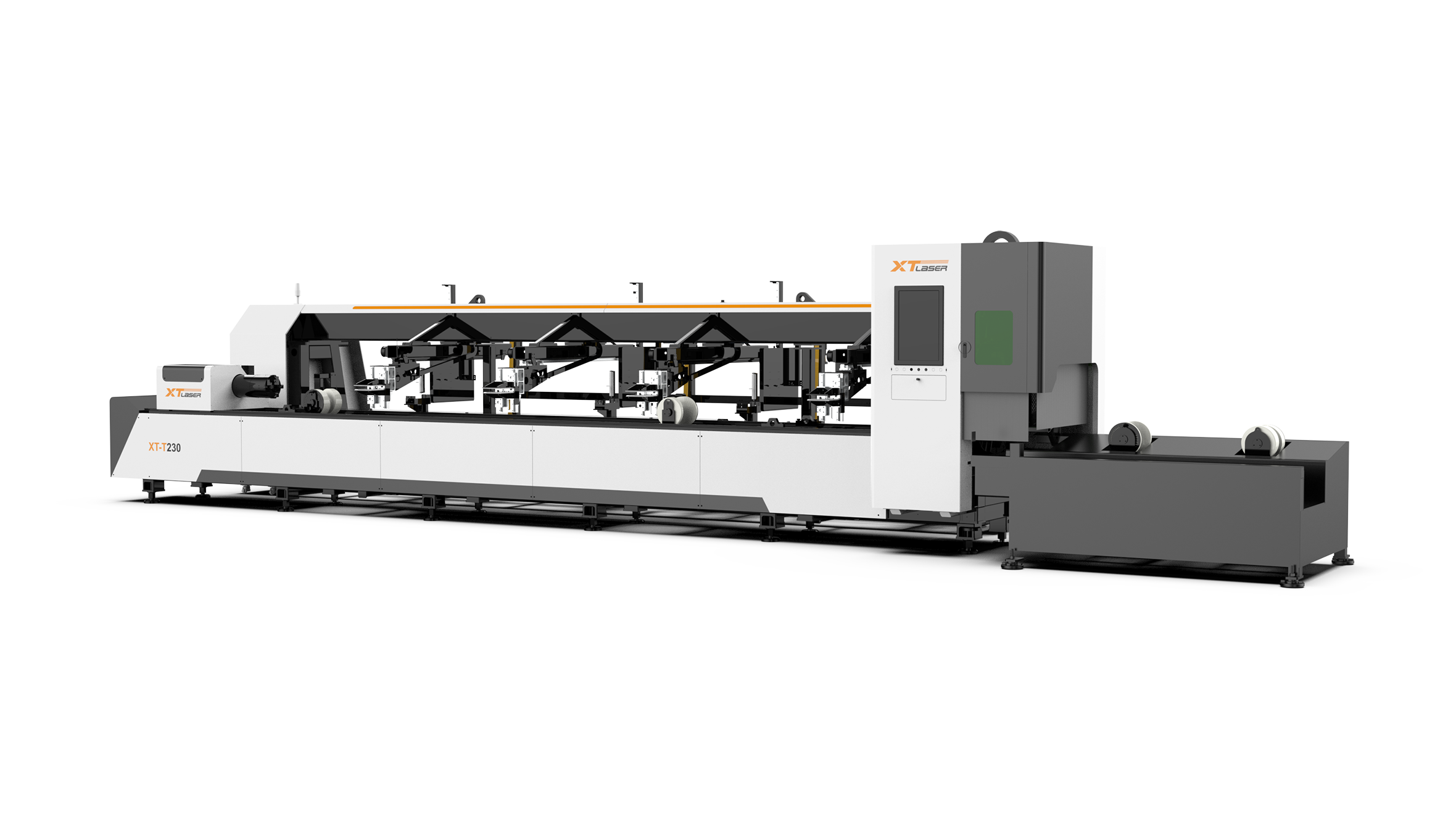

In the realm of precision cutting, the 6000 watt laser cutting machine has emerged as a cutting-edge tool for manufacturers and fabricators. With its advanced technology and exceptional cutting power, this machine offers unparalleled performance for a wide range of materials and applications. In this article, we will explore the advantages of using a 6000 watt laser cutting machine and how it can elevate your cutting processes to new heights. From increased productivity to superior precision, this state-of-the-art machine can deliver outstanding results for your fabrication needs.

Unmatched Cutting Power for High-performance Results

The 6000 watt laser cutting machine packs a punch with its unmatched cutting power, allowing for high-performance cutting with ease. With its high-powered laser, this machine can effortlessly cut through a wide range of materials, including metals like stainless steel, mild steel, aluminum, brass, copper, and more, as well as non-metallic materials like acrylic, wood, and plastics. The 6000 watt cutting power enables faster cutting speeds, resulting in increased productivity and reduced production time. This makes it an ideal choice for high-volume production environments where efficiency is crucial.

Moreover, the higher cutting power of the 6000 watt laser cutting machine also allows it to handle thicker materials with ease. This makes it suitable for a wide range of applications, from thin sheets for intricate designs to thick plates for heavy-duty applications.

Enhanced Precision and Accuracy for Top-notch Cuts

One of the key advantages of using a 6000 watt laser cutting machine is its exceptional precision and accuracy. The focused laser beam produces clean, precise cuts with minimal heat-affected zones, resulting in high-quality finished products. The accuracy of this machine ensures consistent cuts, reducing material waste and minimizing the need for rework or secondary operations. This level of precision is particularly crucial for industries that demand top-notch cuts, such as aerospace, automotive, and electronics.

Additionally, the advanced software and controls of a 6000 watt laser cutting machine allow for intricate and complex designs, making it ideal for customization and unique cutting requirements. This level of precision and flexibility in cutting allows for greater design freedom, resulting in high-quality products that meet customer specifications.

Improved Productivity and Efficiency for Streamlined Operations

The increased cutting power and precision of a 6000 watt laser cutting machine translate into improved productivity and efficiency. The faster cutting speeds and reduced material waste result in higher throughput and decreased production time. Additionally, the advanced software and controls of this machine allow for optimized nesting and scheduling, further enhancing productivity and material utilization. This means you can produce more parts in less time, improving your overall production efficiency and reducing costs.

Furthermore, the ability to automate the cutting process in a 6000 watt laser cutting machine can further streamline operations and reduce labor costs. Automated features such as material handling, part sorting, and stacking can significantly improve the overall workflow and reduce production bottlenecks, leading to increased productivity and efficiency.

Versatility for Diverse Cutting Applications

The 6000 watt laser cutting machine offers versatility in cutting a wide range of materials and thicknesses. From intricate cuts in thin materials to high-speed cutting of thick plates, this machine can handle diverse cutting applications with ease. This makes it suitable for a wide range of industries, including automotive, aerospace, signage, industrial fabrication, and more. The ability to cut various materials with precision