The Future of Industrial Cutting Pipe Laser Cutting Machine

Industrial cutting processes have come a long way over the years, and the introduction of pipe laser cutting machines has been a game-changer. This advanced technology has revolutionized the way pipes and tubes are cut in various industries, offering numerous benefits that can greatly impact productivity and efficiency. In this article, we will delve into the world of pipe laser cutting machines, exploring their capabilities, advantages, and applications in modern manufacturing.

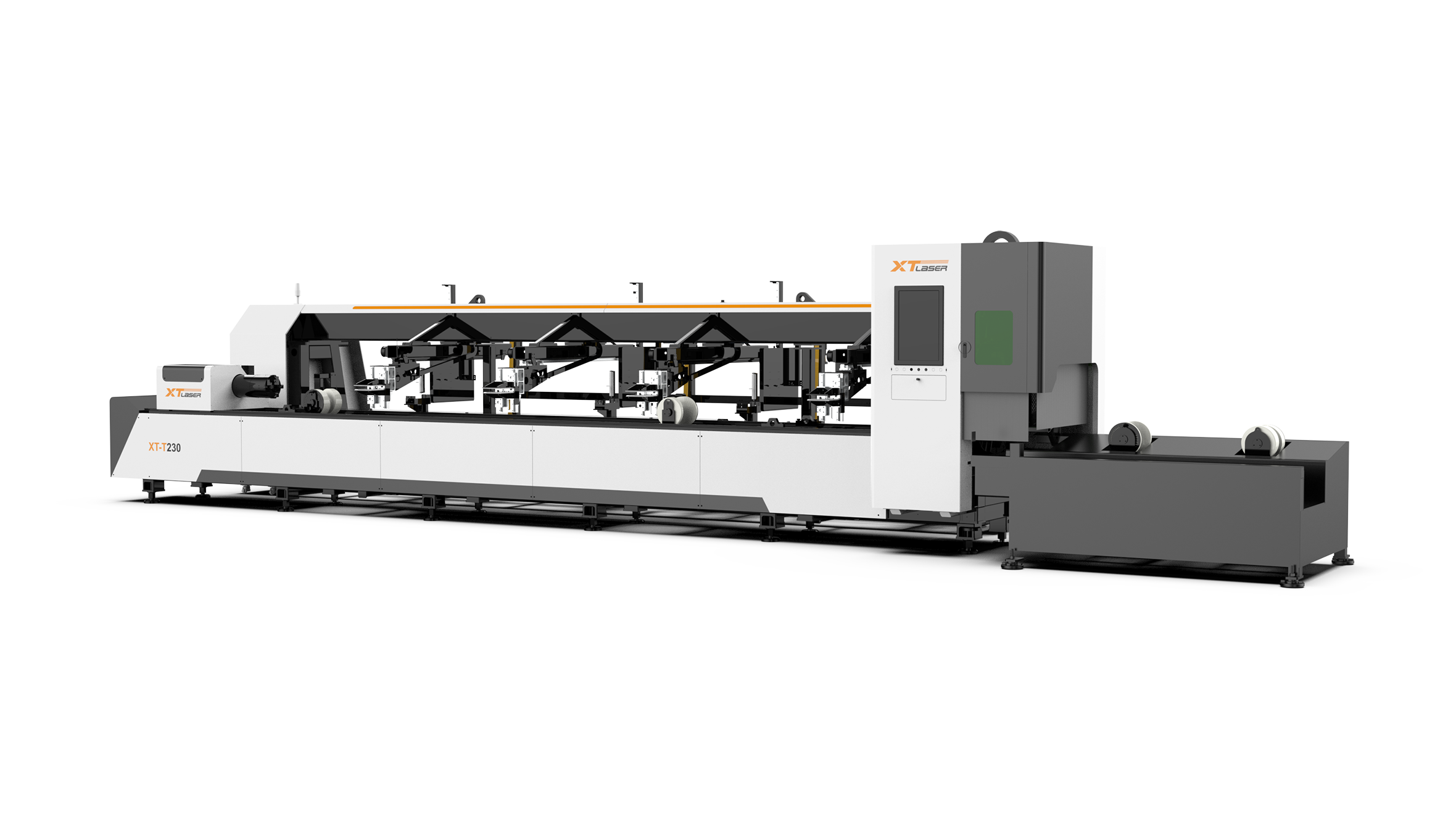

The Basics of Pipe Laser Cutting Machine

A pipe laser cutting machine is a specialized piece of equipment that utilizes laser technology to accurately and precisely cut pipes or tubes. It works by emitting a highly focused laser beam that melts, burns, or vaporizes the material along the desired cutting path. The result is clean, smooth cuts with high precision and repeatability.

Advantages of Pipe Laser Cutting Machine

There are several advantages to using a pipe laser cutting machine in industrial cutting processes:

Precision: Pipe laser cutting machines offer unparalleled precision, allowing for the cutting of complex shapes and patterns with high accuracy. This eliminates the need for additional finishing processes and reduces material waste, resulting in cost savings and improved efficiency.

Versatility: Pipe laser cutting machines can cut a wide range of materials, including metal, plastic, and composites. This makes them suitable for various applications in industries such as automotive, aerospace, construction, and fabrication.

Speed and Efficiency: Pipe laser cutting machines are fast and efficient, capable of cutting through pipes or tubes at high speeds. This translates to increased production output and reduced lead times, helping businesses meet tight deadlines and improve overall productivity.

Clean and Smooth Cuts: Pipe laser cutting machines produce clean and smooth cuts without generating any mechanical force or heat-affected zone. This eliminates the need for additional post-cutting treatments, saving time and resources.

Applications of Pipe Laser Cutting Machine

Pipe laser cutting machines find applications in a wide range of industries and can be used for various purposes, such as pipe fabrication, pipe fittings, exhaust systems, frame structures, and more. They are particularly useful in industries where precision and efficiency are critical, such as aerospace and automotive manufacturing.

Conclusion

Pipe laser cutting machines have become a staple in modern industrial cutting processes, offering unmatched precision, versatility, speed, and efficiency. With their ability to cut a wide range of materials and produce clean, smooth cuts, they have revolutionized the way pipes and tubes are cut, improving productivity and reducing costs for businesses. As the manufacturing landscape continues to evolve, pipe laser cutting machines are poised to play a crucial role in shaping the future of industrial cutting. Investing in this advanced technology can provide businesses with a competitive edge, enabling them to stay ahead in today's fast-paced manufacturing environment.