Mastering Precision Cuts with a 4-Axis Laser Cutting Machine

The demand for precise and intricate cuts in various industries, such as automotive, aerospace, and manufacturing, has led to the evolution of laser cutting technology. One such cutting-edge innovation is the 4-axis laser cutting machine, which offers advanced capabilities for achieving complex cuts with utmost accuracy.

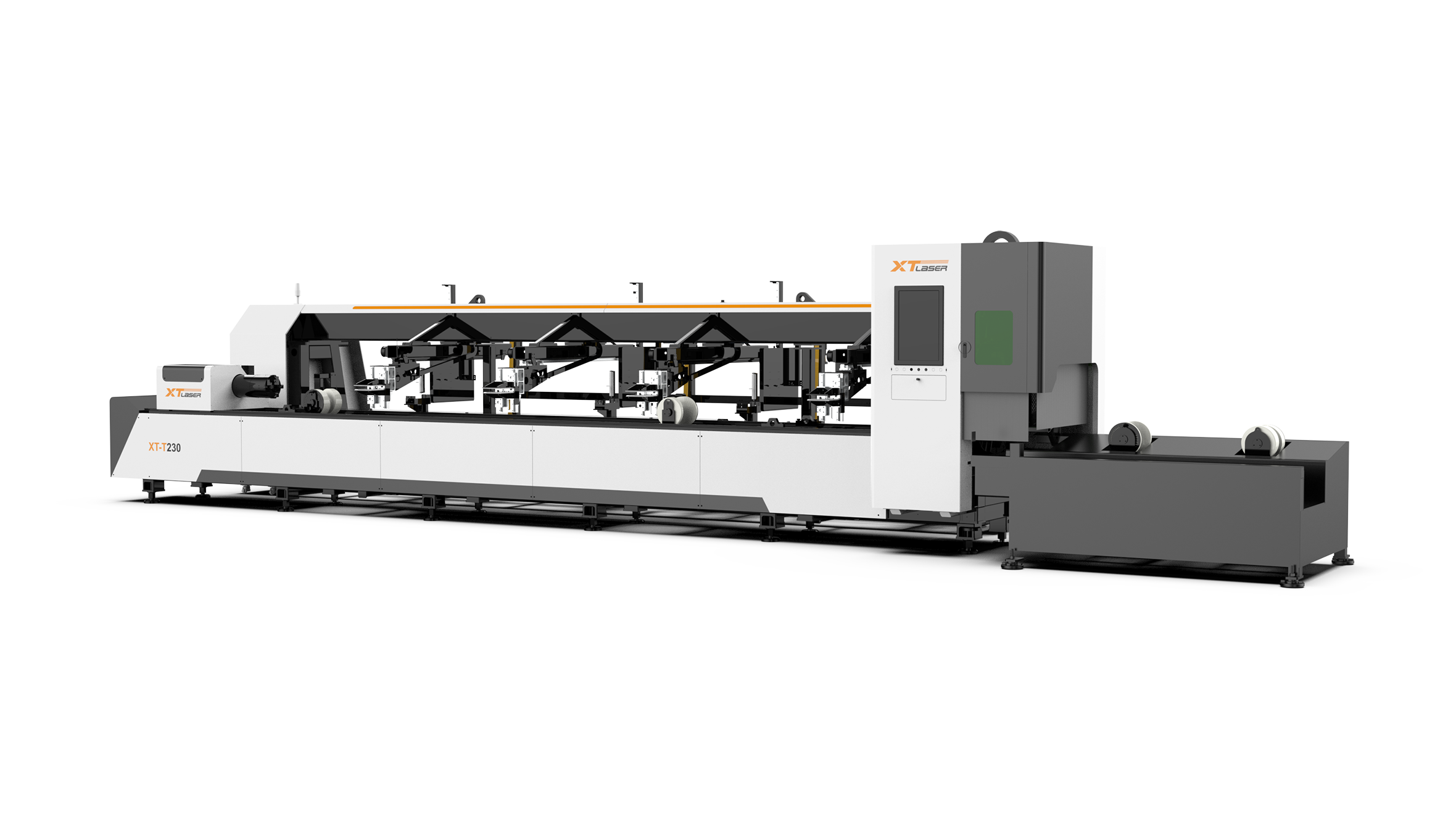

The 4-axis laser cutting machine is equipped with four axes of motion, allowing for greater flexibility and versatility in cutting complex shapes and designs. In addition to the traditional X, Y, and Z axes, it also includes a rotational axis that enables the cutting head to rotate around the workpiece, offering a wider range of cutting angles and positions. This unique feature makes the 4-axis laser cutting machine ideal for cutting curved, beveled, or chamfered edges, as well as creating 3D shapes and contours.

One of the significant advantages of using a 4-axis laser cutting machine is its precision. The multi-axis motion control allows for high accuracy and repeatability, ensuring that even the most intricate cuts are achieved with minimal tolerances. This level of precision results in clean, sharp, and consistent cuts, reducing the need for secondary finishing operations and minimizing material waste.

Another key benefit of a 4-axis laser cutting machine is its efficiency and productivity. The ability to cut complex shapes in a single operation eliminates the need for multiple setups or tool changes, saving time and effort. The rotational axis also enables simultaneous cutting and rotation, increasing the cutting speed and throughput. Additionally, the advanced nesting and optimization software available in modern 4-axis laser cutting machines can optimize material usage, further improving productivity and cost-efficiency.

The versatility of a 4-axis laser cutting machine also makes it a valuable asset in various industries. It can cut a wide range of materials, including metals, plastics, composites, and more, making it suitable for diverse applications such as cutting parts for automotive components, aerospace components, signage, architectural elements, and more.

In conclusion, a 4-axis laser cutting machine is a powerful tool for achieving precision cuts with versatility and efficiency. Its multi-axis motion control, high accuracy, and productivity-enhancing features make it an ideal choice for industries that require complex cutting operations. By investing in a 4-axis laser cutting machine, businesses can gain a competitive edge in their fabrication processes, reduce material waste, and deliver superior-quality products to their customers.